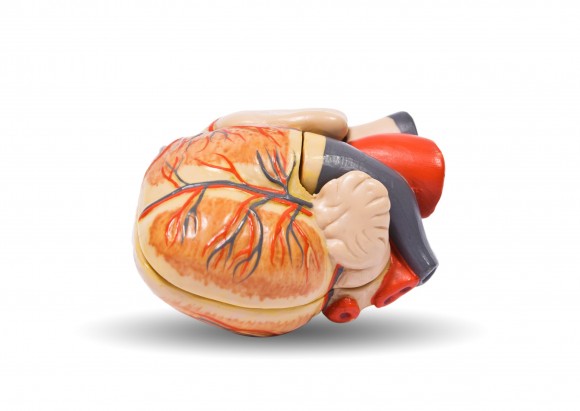

Earlier this year, scientists from Cornell University successfully created an artificial human ear by printing it on a 3D printer. Created by squirting living cells into an injection mold, the ears could replace those of individuals who have lost all or part of their ear in an accident or due to cancer, or for children with congenital defects. It is thought the technology could pave the way for purpose-built replacement organs eliminating the need for organ donation or the possibility of transplant rejection.

3D printing technology is not new. For the past 20 years, designers and manufacturers have been using it to produce prototypes before undergoing the lengthy and expensive process of mass market production. Until recently, though, the prospect that 3D printing could be used by scientists to create body parts or by consumers to clone car parts from metal “inks” seemed like a fantasy from a science fiction movie.

This is changing. Over time, 3D printers have dramatically dropped in price, making it an accessible technology for small businesses and individual consumers as well. Machines that once cost more than $1 million, now cost as little as $400. A quick search on Amazon generates several options and business is starting to boom for 3D printer manufacturers.

Obvious Benefits

Because 3D printing is additive manufacturing, virtually no materials are wasted — a stark contrast to traditional methods where waste in the production process can be as high as 90 percent.

In addition, the process is entirely flexible. There are now a variety of “inks” for 3D printers on the market, which include everything from fiberglass and aluminum to fabric and living tissue, and the design can be amended with limited impact on the production process.

Finally, economies of scale do not matter. It will no longer be necessary to produce 10,000 units to feel a financial or time-savings benefit, allowing for greater customization as well as driving innovation.

3D printing is already having a profound effect on many industries. After the industrial revolution, manufacturing gradually shifted to the East. 3D printing is bringing it back to the factories, small businesses, and home offices of the West. Already, everything from lightweight aircraft parts to buckles for snowboard bindings are being produced using 3D printers. The healthcare industry is seeing the first printed medical implants and prosthetics and working blood vessels have been printed using special tissue.

As we enter a period of manufacturing revolution, it is clear that the traditional product development process will be massively disrupted. As “manufacturing” in its traditional sense is devolved to consumers and physical products become “virtualized,” the shift in the risk landscape is likely to be equally profound.

Insurance Implications

The use of mass-market 3D printing technology will create an army of back bedroom manufacturers. Much of the process will be devoid of the usual rigorous testing found in the traditional manufacturing process with product safety likely to rapidly decline as a result. As new techniques and ink technologies are introduced, latent defects will appear in products that were previously unimaginable and many will not emerge for years, if not decades, after this process has become mainstream.

The world of intellectual property rights management will also be disrupted in the same way that Napster disrupted the music industry at the turn of the century. Peer to peer networks sharing exact replicas of physical goods will emerge and prove almost impossible to control or police in the same way that file sharing networks have destroyed the traditional models for music and film publishers. And with this lack of control will come enormous risk as bootleg car parts, medical implants and domestic appliances flood the market.

But how will all this affect the insurance industry?

Product liability insurers will need to react quickly to the shifting manufacturing landscape. Those that fail to react in time will be left with potentially long-tail liabilities arising from flaws in 3D printing techniques or deficiencies in the new materials. This will require careful research and analysis coupled with a completely revised question set on product liability application forms.

Professional liability insurance for designers will become critical as their digital 3D models are distributed across the globe and interpreted by a wide variety of printers, all configured and calibrated differently. Product related lawsuits will become complicated by arguments over contribution between designers, printing machine manufacturers and end users.

General liability insurers will need to adapt to a world in which intellectual property rights infringement is the rule rather than the exception. Inadvertent infringement will rise as employees are able to download component parts from the Internet and integrate them into new products, bypassing traditional procurement and contracting routes.

Technical innovation rarely comes without risk. With 3D printing at the heart of a quickly-advancing manufacturing revolution, we will see the creation of products that were unimaginable as little as five years ago.

In the insurance industry, we have a major part to play in order to ensure this new world can survive and ultimately thrive. Understanding and embracing these risks is the first step in creating insurance products that will support the modern world.

Topics Tech Manufacturing

Was this article valuable?

Here are more articles you may enjoy.

Zurich Insurance’s Beazley Bid Sets the Stage for More Insurance Deals

Zurich Insurance’s Beazley Bid Sets the Stage for More Insurance Deals  What Analysts Are Saying About the 2026 P/C Insurance Market

What Analysts Are Saying About the 2026 P/C Insurance Market  Nine-Month 2025 Results Show P/C Underwriting Gain Skyrocketed

Nine-Month 2025 Results Show P/C Underwriting Gain Skyrocketed  Insurify Starts App With ChatGPT to Allow Consumers to Shop for Insurance

Insurify Starts App With ChatGPT to Allow Consumers to Shop for Insurance